Networking for greater efficiency

This is a place where even the concrete used in the facade is high-tech. The model factory for the future, which receives funding from the Federal Ministry for Economic Affairs and Energy, is set up in such a way that the equipment, processes, and even the building itself are all part of the same smart network. The aim here is to create a factory that is 40 per cent more energy efficient.

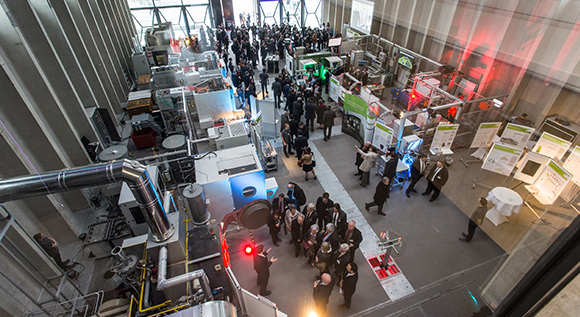

Full-size energy efficiency: a picture showing the interior of the ETA factory and a typical process chain used in manufacturing. © Felipe Fernandes / TU Darmstadt

Full-size energy efficiency: a picture showing the interior of the ETA factory and a typical process chain used in manufacturing. © Felipe Fernandes / TU Darmstadt

Where exactly can we conserve energy in manufacturing, and to what extent? How can we ensure that we still produce to the same standards and without it costing us more? For the first time, scientists from a variety of fields have joined together to try and answer these questions by taking a look at the factory as one system. Looking at individual installations simply wouldn't be enough.

The Darmstadt Energy Efficiency, Technology, and Application Centre (known as the 'ETA factory'), a purpose-built factory fitted with state-of-the-art machinery and equipment, is all about making the best possible use of energy and of passing it on between the different components. The aim is to cut primary energy consumption. New ways of storing, using, and controlling energy are being tested in this factory, which uses a process chain quite common in the metalworking industry to produce steering discs for hydraulic axial piston pumps. Metal cutting, cleaning, and thermal treatment process have all been integrated into this process chain to ensure that the result is meaningful for the entire sector.

It's not about individual machines, it's about their interaction

If you don't sell energy-efficient products and processes, you won't be able to stand your ground on the market for much longer. Growth, employment, and industrial competitiveness are becoming ever more closely linked to the issue of energy efficiency (cf. lead article). Now that many machines have been adjusted to be as energy-efficient as they can possibly be, the next frontier will be to look at the way energy is being used across the entire process chain.

This is exactly what the 37 industrial partners and research institutes that have set up the 'ETA factory' are doing. The factory is organised as a closed system, with all of the installations, appliances and even the building envelope being interconnected by energy networks. This makes it possible for the waste heat generated by the hardening furnace to be pumped into tubes that allow it to be used to provide heat for other parts of the process, say the cleaning bath. Electric flywheel energy storage systems are used to reduce the peak electric load. Heat exchangers, thermal storage systems and absorption refrigerators all form part of the heating network that uses tiny tubes in the concrete facade to cool down the production hall and offices in the summer and to heat them in the winter - all in a very energy-efficient way. The researchers assume that the amount of primary energy used by the ETA factory could be reduced by 40 per cent if areas that used to be viewed as being separate are combined in the best-possible way.

Research for the future, conducted by a university and companies together

The model factory for energy efficiency is firmly integrated into the research and education work conducted in this field at Darmstadt Technical University. The companies involved can also use it for their projects. There is an industrial working group tasked with passing on the results to industry, so that companies can use them for their own premises.

The Federal Ministry for Economic Affairs and Energy provides €8 million in funding for the ETA factory. By doing so, it also promotes research in the field of production technology.