Factory of the future will stabilise the electricity grid

Researchers in Darmstadt are testing the ways in which industrial enterprises can react to grid fluctuations in the future as the share of renewable energy continues to increase. The Federal Ministry for Economic Affairs and Energy is promoting the ‘Phi Factory’ research project.

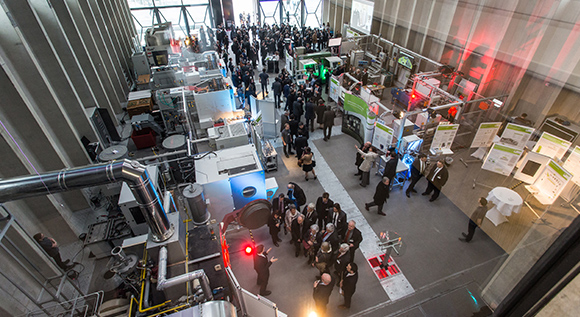

© TU Darmstadt/Felipe Fernandes

© TU Darmstadt/Felipe Fernandes

Over the past years, the Factory of the future has been set up in Darmstadt. It is now ready to be hooked up to the grid. Scientists of the Technical University (TU) of Darmstadt and several companies are engaging in the ‘Phi Factory’ research project launched at the end of 2016 to identify how industrial companies can contribute towards stabilising the electricity grid. Given that the grid will in future be transporting an even higher share of renewable energy, it will be subject to higher fluctuations. Companies from energy-intensive sectors can help smooth out these fluctuations by adjusting their energy needs more closely to grid and generation capacities. This will increase companies’ energy efficiency and open up additional revenue sources as companies will be able to provide new services for the electricity supply system.

Major potential for demand-side management in industry

Demand-side management (DSM) means that if there is a high general demand for electricity in the grid, companies can switch off individual plants without this having a negative impact on their operational processes. In periods of low demand, companies can ramp up their consumption (for more information about this, please see “direkt account”). In Germany alone, the potential for DSM in industry stands at over five gigawatts. This is more than five percent of the peak load measured in the German grid. Around 30 percent of this potential lies dormant in the metal processing industry and the automotive sector. In addition to the three institutes of the Technical University of Darmstadt, two smaller and four larger companies are also involved in the Phi Factory project. The Federal Ministry for Economic Affairs and Energy is providing 4.8 million euro of funding in support of the project up to 2019.

Emergency operation for one hour: factory is to become ready for use in an isolated grid

In recent years, the Technical University of Darmstadt has developed a model factory called ETA Factory, a project which has also been supported by the Federal Ministry for Economic Affairs and Energy. Using the example of a metal-working process, this project looks into all the details of industrial production starting from the production chain up to the building envelope. The aim is to optimise the energy use of the factory. Within the scope of the Phi Factory project, this model factory will be integrated into the grid. Here, the new lithium-ion batteries have an important role to play. These batteries complement the existing kinetic energy storage systems and improve the so-called peak clipping, i.e. they help avoid very high short-term power peaks. Another aim of the project is to make the factory ready for use in an isolated grid in order to enable emergency operation for up to one hour in the event of a power blackout.